Why Water Jet Cutting?

It's simple. Abrasive water jet technology offers your shop increased flexibility and value, and complements other cutting technologies including EDM and laser. MAXIEM is the only water jet company that designs and produces its own pump, machine controller, software, and tables. Full system integration from a single source ensures smooth operation, customer satisfaction, and protection for your investment. Whether you're cutting metal or stone, nearly every shop can benefit from abrasive water jet technology.

Precision and Benefits

Leaves behind a satin-smooth edge, reducing secondary operations

Average accuracy of ±0.005" up to±0.003"

Zero material distortion

Virtually no material limitation

No material delamination, melting or fiber pullout

No oil soaked chips or heat affected zones

Environment & Sustainability

No noxious fumes, liquid or oils used in, or caused by, the machining process

Environmentally "green" system uses only natural garnet abrasive and water in the cutting process

Uses substantially less cooling water than inefficient hydraulic intensifier pumps

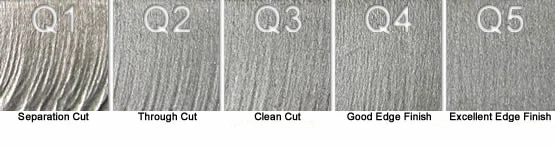

Cutting Quality

Typical Users / Industries Served

Abrasive water jets not only have the power to revolutionize your machining process, they do also grant you the flexibility to service a variety of industries. From medical to energy to defense and everything in between, FLPeng helps you define what's possible in manufacturing.

Industries Served:

- Motor sports

- Knife makers

- Sign makers

- Off road

- Artist

- Aerospace

- Education

- Food Processing

- Medical

- Architecture

- Energy

- Government

- Transportation